Compare Carbon Fiber Plastic Sheet Prices from Trusted Suppliers

In modern times, carbon fiber cost is given much more importance when it comes to different industries. Such lightweight and tough-graded material cuts across the automotive, aerospace, and construction industries, among others. The demands for high-speed and low-cost solutions have increased, and manufacturers are participating in the race to provide competitive carbon fiber plastic sheet pricing. This article guides you through the sphere of reputable plastic factories which excel in providing carbon black filled hdpe and other innovative plastic materials. We will delve into the pros of this kind of products, the reason of that very high demand and the respective prices, and also how to choose properly to have the best deals. Regardless of whether you’re a seasoned professional or beginners, this comprehensive guide will empower you with knowledge to make wise choices.

Discovering Carbon Black Filled HDPE

Carbon black filled HDPE, or high-density polyethylene, is a kind of plastic material which gets a good reputation because of its robustness, high chemical resistance and perfect insulating function. However, the addition of carbon black, a reinforcing filler that is commonly derived from petroleum or coal-tar sources, provides the material with enhanced mechanical properties, such as UV resistance and thermal conductivity.

This versatile material finds applications in a wide range of industries, including:

- Automotive:

Can be used to fabricate car components, battery trays, fuel tanks and several parts that are used under the hood.

- Piping and Plumbing:

Perfect for producing pipes, fittings as well as valves owing to the resistance to corrosion as well as the durability of this material.

- Electronics:

Used in manufacturing insulating parts, cable jacketing, and electronic housings.

- Construction:

Applied to the fabrication of geomembranes, drainage systems, and construction sheets.

Benefits of Carbon Black Filled HDPE

- High yield strength and resilience to impacts

- They have exceptionally strong chemical properties

- High ability to resist situations of corrosion

- UV stability and weatherproofing are also required consideration, as the fabric is to be used outdoors.

- Electrical insulating properties

- Lightweight and effortless to process

Applications in Various Industries

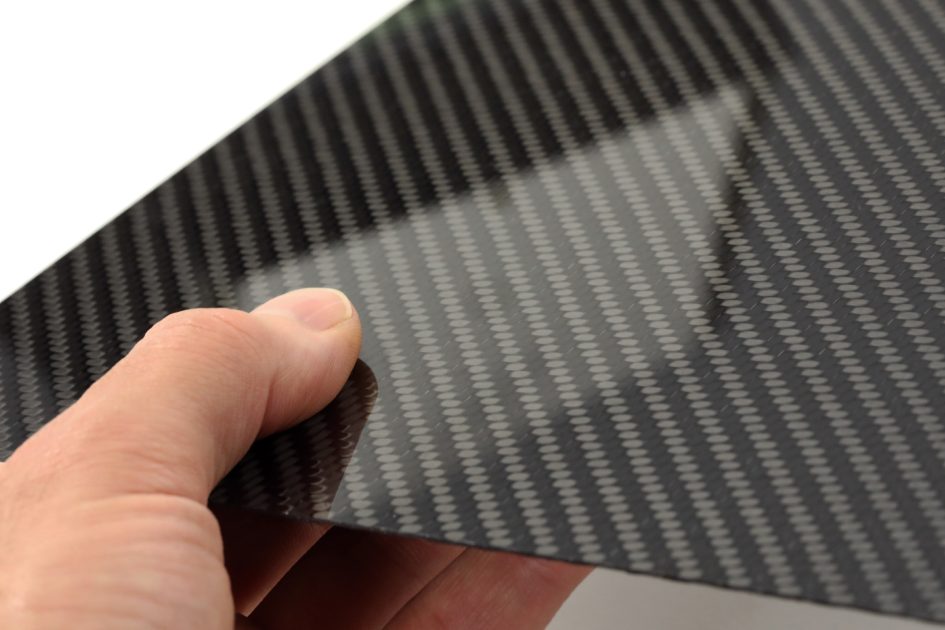

Carbon fiber sheets are used in many different industries because of their high-grade strength and good mechanical characteristics. This material offers an impressive balance of lightness, stiffness, and sturdiness, which is essential in many sought-after areas.

- Automotive Industry:

Carbon fiber plastic sheets are heavily applied in the automotive industry during the fabrication of body panels and spoilers, and they help to meet the issues of lightweight and increase the efficiency and performance of the automobile.

- Aerospace and Aviation:

The aerospace industry uses carbon fiber plastic sheets extensively in making aircraft components – wings, fuselage sections, and cabin panels – making the aircraft lighter to fly and using less fuel.

- Sports and Recreation:

From displaying carbon fiber plastics in sports bicycles and sports goods like golf clubs and tennis rackets to having them as a staple due to their lightweight and durable nature, carbon fiber plastic sheets have been popular for their lightweight and robust characteristics.

- Renewable Energy:

Wind turbine blades as well as other components in the renewable energy sector are made possible through carbon fiber plastic sheets with their advantage of lightness and efficiency.

The Price Factors of Carbon Fiber Plastic Sheet

The carbon fiber plastic sheet price can be impacted by many factors, such as raw material costing, manufacturing procedures, and market demand. One of the essential things that you have to know is these factors, which will enable you to make critical choices when getting these materials.

- Raw Material Costs:

The price of raw materials (e.g. carbon fibers and resins) is one of the important factors for scheduling carbon fiber plastic sheet price.

- Manufacturing Processes:

The manufacturing technique, which includes the resin type, the number of layers, and the curing process, will greatly affect the final cost.

- Quality and Certification:

The price of carbon fiber plastic sheets with higher quality materials and products with specific certifications like aerospace quality often is higher because they are considered premium grades.

- Market Demand:

With the increase in the need for group carbon fiber plastic sheets in different sectors, their prices are prone to vary due to supply and demand forces.

Trusted Rubber Goods Manufacturers

For sourcing high-grade carbon black filled hdpe and carbon fiber plastic sheets, it’s critical to work with reputed rubber goods companies. This market includes manufacturers with a wide expertise in manufacturing precision plastic materials, who can offer the lowest prices, while still being committed to quality guidelines.

Some key factors to consider when selecting a rubber goods manufacturer include:

- Reputation and Experience:

Be sure to find manufacturers that have a history of good performance and plenty of experience in producing the materials you need.

- Quality Control:

For the manufacturer to meet quality control standards and adhere to industry specifications and certifications put in place, make sure that it is a strict requirement.

- Customization Capabilities:

It will be best if you go for an option that provides you with a personalized solution that exactly fits your needs among the variety of options, for example, special dimensions and colours, or surface finish.

- Delivery and Logistics:

Remember to ensure that the manufacturer can adhere to the delivery timeframes and offer reliable logistics support.

Through collaborating with trustworthy rubber goods manufacturers, you will be able to take advantage of the competitive carbon fiber plastic sheet price offers as well as guarantee the quality and performance of materials which you will require for your undertaking.

Conclusion

In an ever-changing advanced materials world, carbon black filled hdpe and carbon fiber plastic sheets become a breakthrough product, these two offers not only strength, and lightness but also durability. Since industries look for higher performance and cheaper solutions, the demand for competitive carbon fiber plastic sheet offerings from reliable rubber goods manufacturers is gaining popularity nowadays.

This article gives a general description of these materials, their use and the factors that determine the price. Knowing the benefits of carbon black, and carbon fiber plastic sheets, together with the factors to be considered when choosing reputable manufacturers, will help you visualize the gains you are likely to get from using these materials.

Be it as an engineer, a designer or a manufacturer, knowledge of the latest developments in the world of advanced plastic materials is indispensable in high-quality projects. Take advantage of the benefits offered by carbon fiber plastic sheets and find a reliable rubber goods manufacturer to open an array of options.